Repair Sleeve Testing and Validation

Full encirclement repair sleeves are very often used for repairing

pipelines. When pipelines are externally corroded or damaged, repair

sleeves provide the hoop stress reinforcement necessary to allow the

pipeline to continue operating at high pressures. So the good news is

that sleeves can be added to repair a damaged pipeline. Unfortunately,

the bad news is that sleeves have to end somewhere. If a buried

pipeline with an added sleeve is subject to differential soil settlement

or ground motion, the ends of the sleeve generate a substantial

discontinuity in the bending stiffness of the pipeline cross section.

Such discontinuities may concentrate bending deformations with the

potential to either wrinkle the carrier pipe or damage the pipe-sleeve

welds.

Full encirclement repair sleeves are very often used for repairing

pipelines. When pipelines are externally corroded or damaged, repair

sleeves provide the hoop stress reinforcement necessary to allow the

pipeline to continue operating at high pressures. So the good news is

that sleeves can be added to repair a damaged pipeline. Unfortunately,

the bad news is that sleeves have to end somewhere. If a buried

pipeline with an added sleeve is subject to differential soil settlement

or ground motion, the ends of the sleeve generate a substantial

discontinuity in the bending stiffness of the pipeline cross section.

Such discontinuities may concentrate bending deformations with the

potential to either wrinkle the carrier pipe or damage the pipe-sleeve

welds.

The project included the analytical evaluation of repair sleeved designs

used in the Trans-Alaska Pipeline System (TAPS) for Alyeska Pipeline

Service Company. Finite element analysis of repair sleeve

configurations was conducted including wrinkling capacity evaluation and

weld fracture assessment. Simulations of field settlement demand

scenarios were followed by design and planning of an experimental

evaluation of pipe-sleeve configurations.

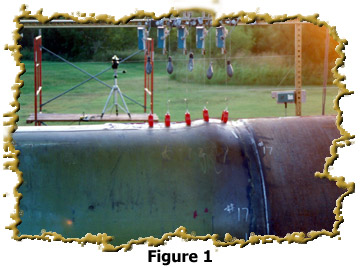

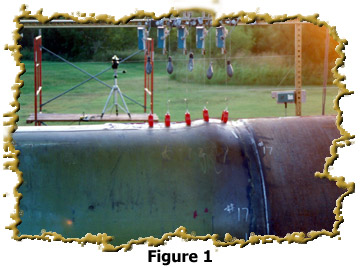

In order to validate the analytical work, SSD planned and directed a

series of full-scale tests of fillet welded pipe-sleeve configurations.

The test, which were conducted on 48-inch diameter by 0.462-inch thick

pipe sections, included the application of internal pressure and axial

forces to simulate fully restrained conditions. Lateral loading was

then applied through four-point bending up to, and beyond wrinkling of

the specimens. Examples of the wrinkled pipe from these tests are shown

in Figures 1 and 2.

At the completion of the experimental program, analytical correlation

studies were also conducted to calibrate PIPLIN analysis models. This

effort lead to the development of a wrinkling segment analysis method

that allows for accurate prediction of pipe wall wrinkling of the TAPS

pipeline, with an without sleeves. The wrinkling segment method

involves the user of nonlinear anisotropic material stress-strain

relationships and pipeline models which include large displacement

effects and strength loss. The results from this method are practical

because they can be used in conjunction with a pipeline monitoring

program based on "smart" geometry pigs.

Home |

Consulting Services |

Project Profiles |

Key Personnel |

Contact Us

SSD, Inc. · 10643 Professional Circle, Suite A · Reno, NV 89521 · Phone (775)-770-1126 · Fax (775)-770-1129 · info@ssdinc.com

Please feel free to

contact SSD for

more information on any of our services.

Copyright ©2011 SSD, Inc. All rights reserved

Full encirclement repair sleeves are very often used for repairing

pipelines. When pipelines are externally corroded or damaged, repair

sleeves provide the hoop stress reinforcement necessary to allow the

pipeline to continue operating at high pressures. So the good news is

that sleeves can be added to repair a damaged pipeline. Unfortunately,

the bad news is that sleeves have to end somewhere. If a buried

pipeline with an added sleeve is subject to differential soil settlement

or ground motion, the ends of the sleeve generate a substantial

discontinuity in the bending stiffness of the pipeline cross section.

Such discontinuities may concentrate bending deformations with the

potential to either wrinkle the carrier pipe or damage the pipe-sleeve

welds.

Full encirclement repair sleeves are very often used for repairing

pipelines. When pipelines are externally corroded or damaged, repair

sleeves provide the hoop stress reinforcement necessary to allow the

pipeline to continue operating at high pressures. So the good news is

that sleeves can be added to repair a damaged pipeline. Unfortunately,

the bad news is that sleeves have to end somewhere. If a buried

pipeline with an added sleeve is subject to differential soil settlement

or ground motion, the ends of the sleeve generate a substantial

discontinuity in the bending stiffness of the pipeline cross section.

Such discontinuities may concentrate bending deformations with the

potential to either wrinkle the carrier pipe or damage the pipe-sleeve

welds.